Your Specialist Provider of Epoxy, Polyurethane Cement & Protective Coating Solutions in Perth WA

Environmentally friendly

Epoxy flooring is environmentally friendly because it contains no solvents and, once cured, cannot pollute or contaminate the environment. Not only is this friendly to the environment, but it is also friendly to your work environment.

Chemical, stain & spill resistant

Epoxy resin flooring will not absorb nasty chemicals due to its non-porous nature, which means it will not stain, is easily maintainable through simple cleaning techniques, and pooling water is virtually ineffective on epoxy resin floors.

Easy To Clean

It is extremely easy to maintain. Using only warm water to clean spills will be enough to maintain your flooring. It does not require harsh soaps or scrubbing as it’s non-absorbent.

Epoxy Is Extremely Safe

Epoxy resins are naturally slip-resistant and fire-resistant. We also offer additives that will create a more gritty texture for added slip resistance if needed. This can be an excellent option for wet areas like pools, bathrooms and locker rooms. These gripping qualities are why epoxy is truly superior to concrete floors.

Impact-resistant For Improved Durability

Epoxy resin floors can be up to 10x stronger than normal concrete floors and are abrasion-resistant, making them perfect for warehouse settings and garage floors.

2+ Year Product & Workmanship Warranty

We offer a 2-year warranty on commercial and a 5-year warranty on residential projects.

The Major Brands Trust Us

You can trust us, because we are trusted and endorsed by quality brands such as Crommelin, Fosroc, Wagon Paints, Rhino Linings, Sika and Parchem.

View: Commercial Epoxy | Industrial Epoxy | Epoxy Flake Flooring

A family-owned business, we’re one of the leading concrete resurfacing and floor work specialists in Perth, Western Australia, driving quality results by using state-of-the-art equipment and years of experience.

We understand more than just concrete floors – we take the time to listen to you and fulfil all your project and design requirements!

At PM Industries, our highly experienced team have all the skills needed to give you the right advice and use the latest technologies available to carry out all projects.

Don’t hesitate to get in touch with us for a free consultation; we will be delighted to visit your home or business and conduct an on-site inspection or offer specification advice.

We pride ourselves on providing our clients with the best customer experience and we know how important it is to take the time to fully understand each job and create a unique solution for each project’s requirements.

We’re specialists in concrete resurfacing and concrete repairs and regularly work in the residential, commercial and mining sectors.

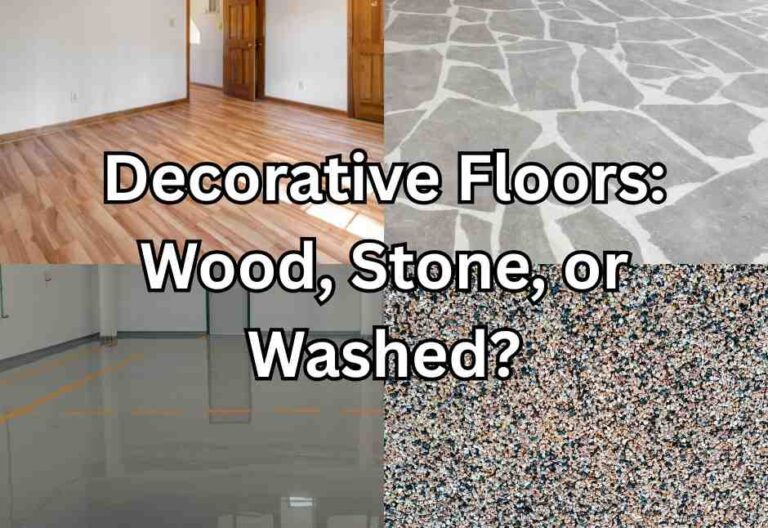

We are able to conduct concrete resurfacing with the perfect colour. But that’s not all you get! Using the latest technology, we are able to provide artistic flair on existing concrete surfaces by incorporating patterns and stencils.

If you’re looking to renovate or fix up your concrete in Perth with a solution that guarantees long-lasting finish and high quality, contact us today for an obligation free quote.

We’re specialists in concrete resurfacing and floor works, and regularly work in the residential, commercial and mining sectors.

Browse our extensive range of domestic, commercial, and specialised flooring types in Western Australia

Expertise you can trust

PM Industries is a family-owned business based in Perth, WA. With over 25 years of experience, we provide a 2-year warranty on commercial and 5-year warranty on residential projects.

Our epoxy resins are mixed and installed by professionals to achieve high durability so all our epoxy floors can withstand high traffic, heavy loads and heavy impacts leaving your floors void of scratches, dents and cracks. PM Industries can guarantee the best quality installation in Perth for long lasting flooring.

Epoxy can easily be maintained by keeping it clear of grit and grime. Maintaining them is as simple as a doing a regular sweep and a mop with warm water avoiding soaps. This will work wonders to keep your floors looking fresh and lasting long.

Yes. We can offer an epoxy resin installation for any setting so there really is no need to compromise on appearance. Have a chat with us about our stone, timber and washed concrete looking finishes as well as the multiple colours and styles we can install.

Epoxy flooring is a type of water resistant protective floor coating used for covering concrete floors.

Epoxy flooring will not absorb any liquid or moisture from the ground or objects that may be placed on the floor. It is commonly seen in public places such as bathrooms, kitchens, basements and other wet areas for its great water resistant properties.

In the event of of flooding the water can simply be squeegeed away.

Yes, but only after proper diamond grinding to ensure adhesion.

All that’s needed for this type of install is for our team at PM Industries to come and put a self levelling coat down first.

This will fill in any imperfections and crevices and allow us to install our epoxy floor coating directly on top.

Epoxy flooring takes about 12-24 hours to dry depending on the application and ambient temperature.

We recommend not walking on it for 24 hours and to refrain from placing objects on it for 2-3 days.

It can take 1-2 weeks to fully cure so we recommend not driving on it during this time.

Once fully cured its perfectly capable of taking heavy traffic.

Epoxy resin floors are quite easy to clean. simply moping without harsh chemicals and a regular sweep or vacuum will do the job and keep your resin flooring lasting long.

Epoxy floors are extremely durable.

They are resistant to chemicals and are abrasion resistant which makes them perfect for commercial and industrial applications.

They can withstand heavy impacts and loads and when taken care of can last many years.

Epoxy flooring typically lasts up to 20 years and can be pushed as long as 30 years with the correct maintenance.

Don’t expect anything less than 10 years minimum when installed correctly.

Get a free consultation & quote